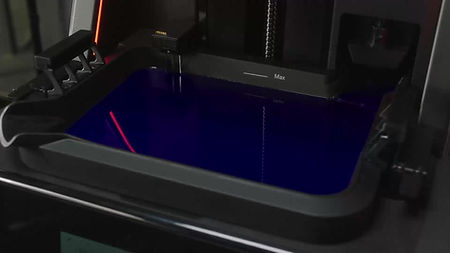

LCD 3D Printer

LCD 3D printing uses a liquid crystal screen and light-curing resin to create three-dimensional objects. UV light projected through the LCD screen solidifies the resin layer by layer. Unlike SLA 3D printing, which uses a single laser point, LCD 3D printing utilizes the entire screen as a light source, exposing one layer at a time for faster printing speeds. The LCD screen displays the pattern, and UV light cures the exposed resin. The platform then lowers, a new layer of resin is added, and the process repeats until printing is complete. LCD 3D printing offers relatively low cost, fast printing speeds, and is well-suited for producing fine, small-scale models.

UltraCraft Reflex

LCD 3D Printer

.Fully Interconnected Workflow

.Smart AI Peeling Force Management

.Minimal Contact with Resin

.Optimized Curing for Greater Material Performance

Your All-in-One Production Platform

The UltraCraft Reflex Combo is an all-in-one smart LCD 3D printing system that seamlessly integrates printing, washing, and curing processes. Its fully interconnected workflow and advanced AI algorithms eliminate the need for manual parameter adjustments, enabling anyone to easily achieve commercial-grade results.

Intelligent Workflows

Auto Zeroing & Intelligent Assisted Levelling

Auto-zeroing and smart-assisted levelling ensure easy and accurate printer setup, providing a worry-free printing experience. Setup takes only minutes. Auto-zeroing ensures each print starts from the correct position, while smart-assisted levelling provides precise feedback, minimizing the need for manual adjustments.

Resin Level Detection & Auto-Refill

The resin level detection system accurately monitors resin levels (±5g accuracy) and identifies the resin type throughout the printing process. Automatic refills are initiated before and during printing as needed, ensuring uninterrupted operation.

Temperature Monitoring & Auto-Heated Tray

The auto-heated resin tray maintains optimal printing temperature throughout the process, even in cold environments. The temperature increases from 50°F (10°C) to the optimal 73°F (22°C) in just 20 minutes, ensuring successful prints.

Smart Usage Tracking

An NFC detector tracks the release film's lifespan, records the number of printed layers, and notifies users when replacement is needed.

Print Status Monitoring

The system monitors your printer's status and provides notifications if any errors are detected.

Peeling Force Management

The UltraCraft Reflex LCD 3D printer uses intelligent peeling force management to analyze and automatically optimize peeling parameters for each layer, ensuring worry-free printing and improved results. This can increase printing speed by up to 40%*.

(*compared to LCD 3D printers without this technology.)

Maximized

Printing Success & Surface Quality

Powerful Algorithms for Enhanced Printing Results

The UltraCraft Reflex LCD 3D Printer utilizes powerful algorithms to optimize print quality:

3D Anti-aliasing

This technology reduces surface roughness, resulting in smoother prints and significantly improved surface quality and clarity.

WDR Fusion+ Algorithm

Multi-layer analysis and automatic compensation reduce peeling forces, improving surface clarity. Balanced exposure maintains model details and increases print success rates.

PICK Recognition

This technology identifies the printed model and support structures, then exposes them independently to create stronger, thinner supports. This facilitates support removal and improves the surface quality of the printed product.

Bringing Your Ideas to Life in Detail

The high-precision finished products produced by the UltraCraft Reflex LCD 3D printer allow you to preview excellent results, from initial concept and prototyping through to final production.

XY Precision

Z-axis Layer Thickness

33μm

30μm

Consistency

Restoration

±16μm

90.6%*

*Data from HeyGears Lab by reverse-scanning a printed model with a 0.05 mm tolerance.

<<< Model designed by Kyoushuneko Miniatures.

Minimum Print Detail: 0.136mm*

*Tested with UltraPrint PAP10 Precise Detail Resin

Zero-Tolerance Assembly Results*

Models require no design tolerances, and good assembly results can still be achieved.

*Tested with UltraPrint PARP10 Rapid Prototyping Resin.

Reliable & Consistent Productivity

Achieve reliable results with over 93% consistency across more than 1,000 times of printing, enabling confident scaling of production.

Consistent Results Across the Build Plate

The light uniformity calibration system ensures at least 90% uniformity across the entire printing panel, enabling consistent print results regardless of print placement.

Consistent Quality Over Time

By monitoring and recording light source aging data, the system provides automatic light intensity compensation, ensuring consistent print quality throughout the printer's lifespan.

End-to-End Intelligent and Streamlined Production

Intelligent automation streamlines your printing process, from design to finished product.

Zero Parameter Settings Required

A new 3D printing strategy, developed through simulations across multiple project types, offers ready-to-use preset modes. This simplifies the process, enabling even novice users to easily participate in and learn 3D printing.

Premium Hardware

The UltraCraft Reflex LCD 3D Printer boasts premium hardware components for superior performance and longevity.

Perforated Steel Build Platform

Offers extended service life, reduced distortion, and improved adhesion.

Industrial-Grade Z-Axis Ball Screw

Ensures exceptional precision with a Z-axis repositioning accuracy within ±0.05mm. This precise travel for each layer results in smooth, low-drag operation.

Long-Lasting Release Film

Provides a service life of ≥45,000 print layers and is easily replaceable.

6K Mono Screen

Features a native XY pixel resolution of 33 µm, a size of 192 x 121 mm, and a resolution of 5760 x 3600.

COB Light Source

Utilizes a freeform surface lens for light uniformity ≥94% and a draft angle <2°.

TrueUV Light Source System

Achieve commercial-grade results with injection-molded-like quality.

High-Energy 385nm UV Light Source

Delivers a 1.5x more powerful resin curing effect than the printers which using 405nm UV wavelength.

Variable Wavelength UV

The system automatically matches the UV wavelength to the specific resin for optimal results.

Enhanced Material Performance

The unique customized lens ensures balanced light distribution, curing cross-linking rate exceed 60%, the tighter polymerization significantly improved material performance.

More Advanced Materials Available

UltraPrint resin is formulated to maximize performance when used with the UltraCraft Reflex's TrueUV light source. High-energy UV wavelengths cure resin materials more effectively due to greater energy transfer. The high-energy 385nm UV wavelength delivers a 1.5x stronger curing effect than 405nm, enabling the use of more advanced materials for enhanced print performance.

UltraPrint PAT10 Transparent Resin

88% light transmittance and yellowing resistance.

UltraPrint Elastic Resin

20 N/mm tear strength.

UltraPrint High Strength & High Toughness Resin

109 MPa flexural strength.

UltraPrint-Modeling PAU10

Offers ABS-like strength, toughness, and flexibility.

UltraPrint-Design CMYK

Mixable colors for a full spectrum of possibilities.

UltraCraft Reflex

Build Volume:192*121*220mm

Build Height:220mm

Print Speed:27mm/h (Layer Thickness: 50µm)

Dimension:400*420*573mm

Weight:25kg

Voltage:100-240V (~50/60Hz)

Rated Power:350W

UltraCraft Wash

Washing Volume:198*123*150mm

Washing Time:≤4mins

Washing Agent:Ethanol (≥95%)

Dimension:351*272*168mm

Weight:8kg

Voltage:100-240V AC

Rated Power:80W

UltraCraft Cure

Curing Volume:198*124*220mm

Curing Time:≤1hour

Max Curing Temp:60-80°C

UV Wavelength:405nm + 365nm

Dimension:370*387*456mm

Weight:12kg

Voltage:100-120V AC; 200-240V AC

Rated Power:350W