CNC & Laser Engraving Machine

CNC (Computer Numerical Control) technology uses computer programs to automate machine operation. It precisely controls the movement of cutting tools or other instruments via pre-programmed coordinates and instructions, performing tasks such as precision cutting, engraving, and drilling.

Laser engraving uses high-energy laser beams to engrave or cut materials. A computer controls the laser beam's movement and intensity to accurately engrave or cut patterns and text onto material surfaces.

Carvera is an intelligent desktop CNC milling and laser engraving machine featuring innovative Auto Tool Changer, Auto Probe, Vacuum System, and Laser Engraver. Accessible to both beginners and experienced users, Carvera simplifies precision machining for everyone.

Pack of Smart Features

Auto Tool Changing & Auto Probing

Without automated tool changing and probing, users would manually change tools and perform probing between each process — a tedious and time-consuming task, especially when milling printed circuit boards (PCBs) or engraving complex objects.

Carvera streamlines this process. Whether levelling, cutting, cleaning, drilling, or engraving, Carvera automatically switches to the correct tool, ensuring accurate results. From now on, you just have to focus on your design and let Carvera do the rest!

Built-in Dust Collection

Desktop CNC milling and engraving machines typically lack dust collection due to size constraints. Carvera innovatively integrates a dust collection system, ensuring a clean and tidy workspace throughout the entire process.

Integrated Laser Module

Laser engraving is a remarkable technology capable of creating intricate patterns and markings on a wide range of materials. Carvera integrated 2.5W diode laser module allows seamless switching between CNC milling and laser engraving, enabling users to engrave on materials such as paper, wood, plastic, leather, and fabric.

Optional 4-Axis Module

Carvera's 4-axis simultaneous machining capabilities enable the processing of cylindrical, double-sided, and 3D objects, unlocking endless creative possibilities. Furthermore, you no longer need to be limited by materials. Carvera supports a wide range of materials, from plastics and wood to metal, you can create beautiful, realistic and unique crafts with the help of Carvera.

Endless Possibilities

Make PCBs for your electronics

Carvera revolutionizes PCB manufacturing, eliminating long wait times associated with traditional chip fabrication plants. Simply load your PCB design file into Carvera's software; its automated tool changing and levelling functions quickly produce your board. Carvera dedicated solder mask removal tools and laser modules for screen printing and engraving further simplify subsequent soldering. This streamlined workflow accelerates design, manufacturing, testing, and optimization, reducing time to market and significantly lowering R&D costs.

Make strong parts for your robots

CNC milling and engraving are indispensable for creators building drones from carbon fiber or robots from metal parts. The high cost of custom-ordered parts for prototyping or building these products is eliminated with Carvera, which enables users to complete the entire process themselves, significantly improving production speed, quality, and cost-effectiveness.

Art Creation

Carvera empowers artists and designers to create a wide range of merchandise, from jewelry and wood carvings to castable molds. Its material versatility makes it ideal for producing sellable goods or personalized gifts. Carvera's compact size also allows for on-site customization at events and markets.

Make useful stuff to upgrade your life

Frustrated with mass-produced products that don't quite meet your needs? Carvera empowers you to customize existing items or create entirely new, personalized objects. Its versatility allows you to design and manufacture virtually anything imaginable, improving your life and potentially opening doors to new business ventures. Share your creations with the world and discover the possibilities.

High Quality & High Precision

Sturdy & Fully Enclosed Frame

Carvera's robust construction features a metal alloy frame and a stainless steel and engineering-grade ABS+PC outer casing, combining aesthetics with durability. The fully enclosed design minimizes dust dispersal and reduces operating noise, ensuring accurate and safe operation.

Linear Rails & Ball Screws

Carvera's axes utilize high-quality linear rails and ball screws for vibration-free stability and precise motion, ensuring smooth, durable, and highly accurate operation.

Closed Loop Servos

Carvera integrates a closed-loop control system into its compact design, enhancing accuracy and precision. A collision detection system immediately stops the motor upon impact, preventing damage to tools and the machine itself.

Fully Assembled, Fine Tuned & Tested

Each Carvera undergoes rigorous professional assembly, fine-tuning, and testing before leaving the factory. Comprehensive software and hardware testing ensures quality control and safe shipment.

xTool M1

Your Craft Making Partner

2-in-1

Versatile Craft Use

Combining laser engraving and blade cutting capabilities in a single machine expands material options and simplifies the creation of intricate crafts.

The manufacturer conducted a series of professional tests on xTool M1 to ensure it meets public needs.

The xTool M1's superior quality reflects the manufacturer's commitment to excellence. Rigorous testing ensures the product meets public needs.

≥ 7,200 hours

of laser tube aging tests

(full power, 45 prototype machines)

≥ 3,195 hours

of motor aging tests

(Accumulated by 6 prototype machines)

≥ 2,000 hours

of power stability tests

(Accumulated by 3 prototype machines)

≥ 2,880 hours

of extreme environmental tests

(7 conditions with 25 prototype machines)

≥ 48,000 times

of openning & closing the lid

≥ 20 rounds

of reliability tests

(drop tests , impact test, vibration test, etc.)

Beyond product quality, xTool maintains rigorous standards throughout its research and development process, from meticulous supplier selection to thorough product testing, no detail is overlooked.

Pre-Shipment Inspections

xTool perform 7 rigorous inspections on each package before it ships to ensure it meets their exacting standards.

100% Scenario Testing

xTool conduct comprehensive 100% scenario testing to verify all product functionality and performance.

Best Sourcing

xTool source materials only from the most reliable and high-quality suppliers.

One for All Crafters

Smarter Camera

Easier Operations

xTool M1 has a built-in 16MP high-resolution camera, which makes all operations visualized and easier. It can even work in batches to improve your work efficiency.

One-click batch fill

Simply click the "Smart Fill" function to easily and efficiently apply patterns to multiple items, making batch processing easy and convenient.

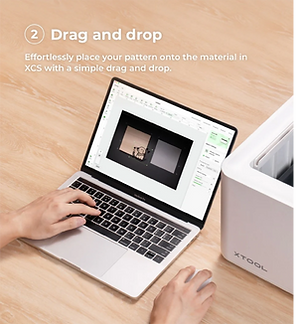

Real-time drag and drop

You can directly see the entire working area through the camera, and just drag the pattern to fill the materials.

As Easy as 1-2-3

More possibilities for crafts

Rotary Working

With the RA2 Pro (included in the deluxe or ultra deluxe kit), seamless adaptation to cylindrical objects expands your craft creative horizons.

Higher Working Space

For taller objects, the Riser Base (included in the ultra deluxe kit) elevates xTool M1's height, enabling engraving without limits. Unleash your boundless creativity.

Safety Features

Care-Free Use at Home

4-Axis 3D Engraving

Embossed text function

Auto precision tool setting

Tool loss compensation

Circulating water tank

Power-off resume engraving

Fully sealed workspace

Spacious Flat Relief Area

General size on the market

K30 workspace dimensions

Large 3D Carving Area

General size on the market

K30 workspace dimensions

High Power & High Speed Spindle

Cutting capacity increased by 40%|Work efficiency increased by 20%

Precision Helical Gear Reducer

Achieve 100:1 reduction ratio, bringing up to 0.1º rotation accuracy experience

Compatible with a Variety of Materials

Jade

Glass / Acrylic

Wood

Shell

Metal

Pearl

Wide Range of Applications

Simple Control System

The portable controller eliminates the need for a separate computer. Its simple interface allows users, even those without prior CNC engraving experience, to quickly master operation after watching the manufacturer's instructional videos. CNC engraving projects can be completed with ease.

Auto Tool Setting

Automated tool setting eliminates errors associated with manual methods, ensuring precise and convenient CNC engraving. The K30's advanced tool damage compensation feature automatically adjusts for tool length reduction due to wear, maintaining consistent engraving quality.

High-Performance Coolant

High-speed spindle rotation generates significant frictional heat. The K30's coolant system rapidly cools the spindle, maintaining optimal operating temperatures for the bearings and spindle itself, ensuring high-precision engraving. This high-performance coolant offers a 35% improvement in cooling efficiency compared to traditional coolants.

Circulating Water Spray System

The integrated circulating water spray system, used in conjunction with the high-performance coolant, reduces coolant consumption and overall costs. The system also pre-cools the spindle and assists in chip removal. This synergistic combination of coolant and spray system protects equipment and enhances finished product quality.

Water Level Monitoring Window

The K30's large-capacity water tank includes a water level monitoring window, allowing users to easily check the water level and identify debris accumulation. Low water levels can lead to dry grinding, accelerated tool wear, tool chipping, workpiece damage, and other hazards. Regular monitoring via this window helps extend machine lifespan.